PID

Simulator -

Get This PID simulation Software for the basics

|

|

|

|

|

"Gain a better understanding of PID basics with our interactive PID

simulator. Simulations include furnace temperature controller and a tank's fluid level control."

PID

Control Basics

Tutorial

The above picture is just a screen shot, not

animated like in actual PID simulator training program.

PID

Simulator - Tutorial Screenshots

| PID

Control Basics Tutorial Ver. 6.0 |

| ESBN: RM1-6003-5050-7468 |

| Description:

In advanced control systems, sometimes it help clarify

understanding if you can just experiment with the PID

controller

without causing damage or production scrap.

That is the purpose of this PID simulator, to

experiment with each PID simualtion. Proportional integral

control tuning is performed via an interactive PID controller

after giving you the PID basics.

PID basics is described in 12 interactive screens of text,

graphics, and animation. PID (Proportional, Integral,

Derivative) control is the state-of-the-art way to control

continuous processes such as furnace temperature control, liquid

levels and flow, process speed and pressures. The program first explains the

PID basics and

draws proportional, integral, and derivative outputs as you vary

an error signal. Then the program allows you to actually

"tune" an example furnace temperature controller and liquid level

controller by adjusting Gain, Reset, and Rate for the best

control.

We call attention to this little PID Basics tutorial for our facilities

maintenance training customers primarily because building environmental

control utilizes a PID controller, as may pump controllers, boiler

controllers, etc. Even HVAC technicians, both commercial and

residential may be interested in this PID tutorial as the

temperature controller in most homes, uses PID control. An interesting note,

you may not realize, the cruise control in your car utilizes a PID

control also. A PID control function is available in most PLCs for

process control too. For example in plastic manufacturing

facility, an extruder's speed will be controlled by a PID loop circuit, as

well as many applications requiring temperature, level, flow,

speed and pressure control.

According to Wikipedia, "A proportional-integral-derivative

controller (PID controller) is a control loop feedback

mechanism used in industrial control systems. In an industrial

process a PID controller attempts to correct the error between a

measured process variable and a desired setpoint by calculating

and then outputting a corrective action that can adjust the

process accordingly." You can read about it at Wikipedia,

but true understanding comes from experimenting with our PID

tutorial, a hands on approach.

Who

Can Benefit

Facilities maintenance and plant maintenance

personnel as well as engineering who have not had formal PID

control training, may find this PID

control tutorial increases both their knowledge and their

understanding of PID tuning. This PID tutorial is a great aid for

students who are currently or about to cover the topic of

proportional integral derivative control. Those with previous

training in the art of proportional integral derivative control,

may find this tutorial a good refresher and may gain better

understanding of PID tuning than in their original PID control

training.

The "Add

to Cart" Button below is for the Single User Version ONLY!

|

|

Email confirming

CD order sent immediately after purchase.This email

will also have a download link for a free Ebook about the

"True Cost of Downtime", that we give to all our

customers. If you ordered the Download version or CD version,

confirmation mail will have download link to training software. A

second email with shipping details for those who ordered CD, will

be sent within 24 hours.

|

Download Version: Price:

US$19.95 - Download

Now >

|

CD Version: Price:

US$29.95 Order

CD Now >

|

Automated download

system is powered by our preferred method of payment, secure Pay Pal.

(No account is needed to purchase using paypal.

After purchase, you receive a confirmation email.) If you

prefer us to manually process your order or would like to mail or fax

order in, please click CD

and Book Order Form on our secure servers at BIN95.

PID Simulator Sample Screenshots

PID Basics Tutorial after drawing the integral of a

user-generated error signal.

"... The proportional integral control output is dependant not

only on the amplitude of the error, but on how long the error has

persisted."

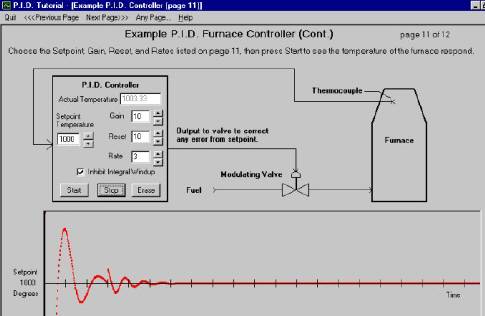

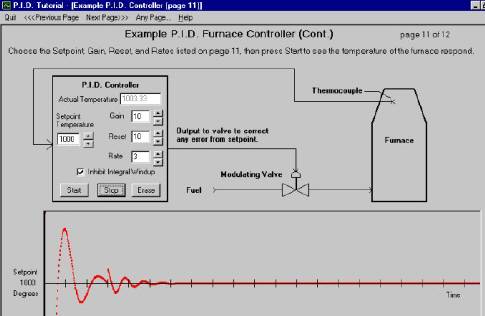

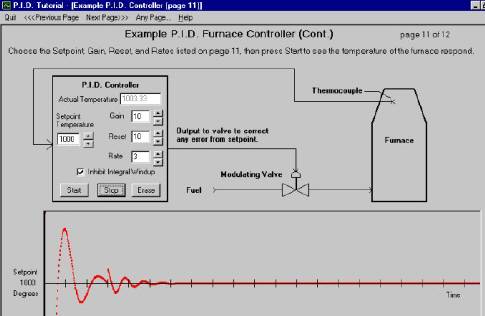

Example PID Furnace temperature control being tuned

by you.

"... You choose the set point, gain, reset and rate, then

press start to see the furnace temperature control respond."

Example PID Level controller being tuned by you.

"... This section gives you example PID tuning settings to

try and see the reaction of the tank's fluid level."

|

Email confirming

CD order sent immediately after purchase.This email

will also have a download link for a free Ebook about the

"True Cost of Downtime", that we give to all our

customers. If you ordered the Download version or CD version,

confirmation mail will have download link to training software. A

second email with shipping details for those who ordered CD, will

be sent within 24 hours.

|

Download Version: Price:

US$19.95 - Download

Now >

|

CD Version: Price:

US$29.95 Order

CD Now >

|

Automated download

system is powered by our preferred method of payment, secure Pay Pal.

(No account is needed to purchase using paypal.

After purchase, you receive a confirmation email.) If you

prefer us to manually process your order or would like to mail or fax

order in, please click CD

and Book Order Form on our secure servers at BIN95.

|

"Gain a better understanding of PID basics with our interactive PID

simulator. Simulations include furnace temperature controller and a tank's fluid level control."

PID

Control Basics

Tutorial

The above picture is just a screen shot, not

animated like in actual PID simulator training program.

PID

Simulator - Tutorial Screenshots

| PID

Control Basics Tutorial Ver. 6.0 |

| ESBN: RM1-6003-5050-7468 |

| Description:

In advanced control systems, sometimes it help clarify

understanding if you can just experiment with the PID

controller

without causing damage or production scrap.

That is the purpose of this PID simulator, to

experiment with each PID simualtion. Proportional integral

control tuning is performed via an interactive PID controller

after giving you the PID basics.

PID basics is described in 12 interactive screens of text,

graphics, and animation. PID (Proportional, Integral,

Derivative) control is the state-of-the-art way to control

continuous processes such as furnace temperature control, liquid

levels and flow, process speed and pressures. The program first explains the

PID basics and

draws proportional, integral, and derivative outputs as you vary

an error signal. Then the program allows you to actually

"tune" an example furnace temperature controller and liquid level

controller by adjusting Gain, Reset, and Rate for the best

control.

We call attention to this little PID Basics tutorial for our facilities

maintenance training customers primarily because building environmental

control utilizes a PID controller, as may pump controllers, boiler

controllers, etc. Even HVAC technicians, both commercial and

residential may be interested in this PID tutorial as the

temperature controller in most homes, uses PID control. An interesting note,

you may not realize, the cruise control in your car utilizes a PID

control also. A PID control function is available in most PLCs for

process control too. For example in plastic manufacturing

facility, an extruder's speed will be controlled by a PID loop circuit, as

well as many applications requiring temperature, level, flow,

speed and pressure control.

According to Wikipedia, "A proportional-integral-derivative

controller (PID controller) is a control loop feedback

mechanism used in industrial control systems. In an industrial

process a PID controller attempts to correct the error between a

measured process variable and a desired setpoint by calculating

and then outputting a corrective action that can adjust the

process accordingly." You can read about it at Wikipedia,

but true understanding comes from experimenting with our PID

tutorial, a hands on approach.

Who

Can Benefit

Facilities maintenance and plant maintenance

personnel as well as engineering who have not had formal PID

control training, may find this PID

control tutorial increases both their knowledge and their

understanding of PID tuning. This PID tutorial is a great aid for

students who are currently or about to cover the topic of

proportional integral derivative control. Those with previous

training in the art of proportional integral derivative control,

may find this tutorial a good refresher and may gain better

understanding of PID tuning than in their original PID control

training.

The "Add

to Cart" Button below is for the Single User Version ONLY!

|

|

Email confirming

CD order sent immediately after purchase.This email

will also have a download link for a free Ebook about the

"True Cost of Downtime", that we give to all our

customers. If you ordered the Download version or CD version,

confirmation mail will have download link to training software. A

second email with shipping details for those who ordered CD, will

be sent within 24 hours.

|

Download Version: Price:

US$19.95 - Download

Now >

|

CD Version: Price:

US$29.95 Order

CD Now >

|

Automated download

system is powered by our preferred method of payment, secure Pay Pal.

(No account is needed to purchase using paypal.

After purchase, you receive a confirmation email.) If you

prefer us to manually process your order or would like to mail or fax

order in, please click CD

and Book Order Form on our secure servers at BIN95.

PID Simulator Sample Screenshots

PID Basics Tutorial after drawing the integral of a

user-generated error signal.

"... The proportional integral control output is dependant not

only on the amplitude of the error, but on how long the error has

persisted."

Example PID Furnace temperature control being tuned

by you.

"... You choose the set point, gain, reset and rate, then

press start to see the furnace temperature control respond."

Example PID Level controller being tuned by you.

"... This section gives you example PID tuning settings to

try and see the reaction of the tank's fluid level."

|

Email confirming

CD order sent immediately after purchase.This email

will also have a download link for a free Ebook about the

"True Cost of Downtime", that we give to all our

customers. If you ordered the Download version or CD version,

confirmation mail will have download link to training software. A

second email with shipping details for those who ordered CD, will

be sent within 24 hours.

|

Download Version: Price:

US$19.95 - Download

Now >

|

CD Version: Price:

US$29.95 Order

CD Now >

|

Automated download

system is powered by our preferred method of payment, secure Pay Pal.

(No account is needed to purchase using paypal.

After purchase, you receive a confirmation email.) If you

prefer us to manually process your order or would like to mail or fax

order in, please click CD

and Book Order Form on our secure servers at BIN95.

|

|

|

|