Heat Exchangers CBT

|

|

|

|

|

This guide, with skills tests, makes a great animated study

guide for related career skill assessment.

Heat Exchangers

CBT

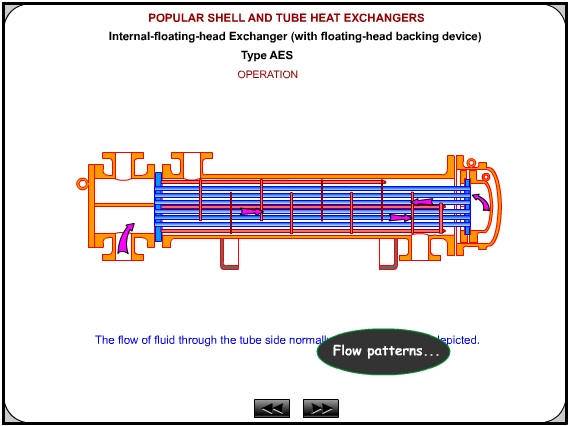

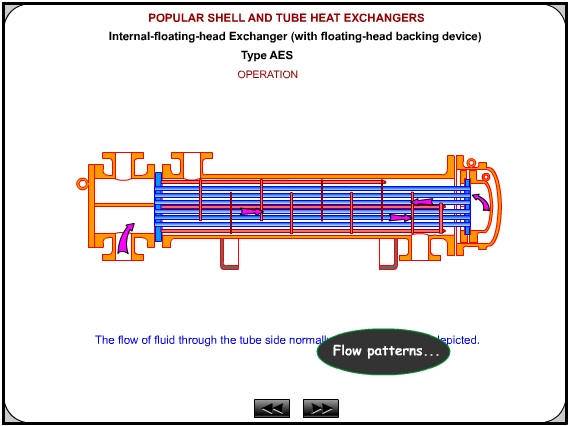

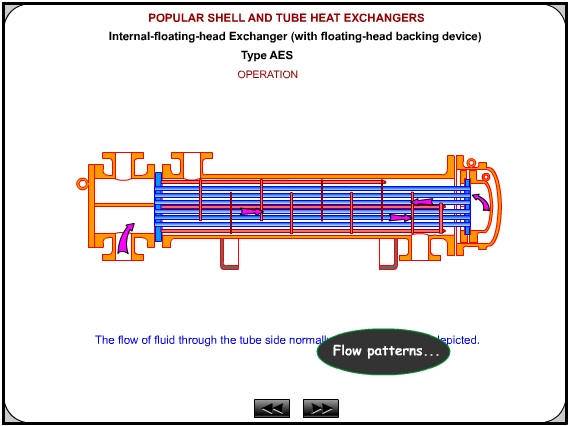

The above picture is just a screen shot,

click for animated demo.

Heat Exchangers CBT Demo - Content

|

Heat Exchangers CBT Software |

| ESBN: II1-6798-6040-KM70 |

| Description:

This computer based training on Heat Exchangers

covers a large range of exchanger types like Shell &

Tube Exchangers (includes TEMA type

classification), Air-Cooled Exchanger, Plate &

Frame (Plate Exchanger), Spiral Exchanger, etc. Detailed

coverage provided on Heat Exchanger Operation &

Maintenance of popular TEMA - AES, BEM, AEP, CFU, AKT &

AJW types.

The focus on Heat Exchanger graphics/animation in the CBT helps

in very clearly understanding Heat Exchanger operating/working

principle & Heat Exchanger maintenance procedures like testing

and Heat Exchanger repair. The Heat Exchanger

training program provides detailed explanations of Heat

Exchanger assembly and dismantling. Animated

scenes give a deep insight into how Heat Exchangers work.

- Large range of Heat Exchangers covered

- Popular Exchangers like "Shell and Tube" covered in great

detail

- Extensive 2D / 3D graphics, models and animations

- Games on TEMA selection - over 250 exchangers can be

assembled!

- Glossary, Skills Tests and Certificate Printouts

Special Bonus:

Upon

request, we will embed your company logo (replacing the BIN95

logo) in the compressor training software, both to give you a

customized feel as well as for added protection of your new

company software. (Please note URL of

company logo in comment are when ordering or email your logo to

us, if you would like to take advantage of this new feature.)

Who

Can Benefit

Students as well as maintenance and engineering

personnel who have not had formal training, will

find this heat exchanger CBT increases both their knowledge and confidence

when working with most compressors and compressor control

systems. Those with previous air

compressor training may find this tutorial a good refresher and

may learn some important information not covered in their original

air compressor training.

The "Add

to Cart" Button below is for the Single User Version ONLY!

Hardware

Lock

The Heat

Exchangers CBT is different than our other training software

in the respect that it utilizes a "Hardware Lock"

licensing method. Many users have requested that they be able to

use the CD on multiple computers, like when working on the office computer and on their home

computer. This Hardware Lock method allows users to install the software on as many computers as they like.

They need only plug the key in which ever computer they are

currently wanting to use the software on. This copyright method

also works great for the class room environment.

Please click for multiple Workstations

and Network

Editions and special school pricing.

|

|

Email confirming

CD order sent immediately after purchase. After CD and Hardware Lock ships, an email will

be sent to confirm shipment.

|

|

|

|

|

|

|

Automated download

system is powered by our preferred method of payment, secure Pay Pal.

(After purchase, you receive a confirmation

email.) If you prefer us to manually process your order

or would like to mail or fax order in, please click CD

and Book Order Form on our secure servers at BIN95.

Course

Table

of Contents

- 1. Different Types of Heat Exchangers

- 1.1. Introduction

- 1.2. Shell and Tube Heat Exchanger

- 1.3. Air Cooled Heat Exchanger

- 1.4. Spiral Plate Heat Exchanger

- 1.5. Plate and Frame Heat Exchanger

- 1.6. Plate and Fin Heat Exchanger

- 1.7. Evaporative Cooled Heat Exchanger

- 1.8. Spiral Tube Heat Exchanger

- 1.9. Double Pipe Heat Exchanger

- 1.10. Bayonet Heat Exchanger

- 1.11. Patterned Plate Heat Exchanger

- 1.12. Mechanically aided (Scraped Surface Exchanger

& Thin Film Exchanger)

- 1.13. Jacketed Vessels

- 1.14. Fired Heaters

- 1.15. Regenerative Heat Exchanger

- 2. Detailed Description of Popular Shell and Tube

Exchangers

-

- 2.1. Principle of operation of Shell

and Tube Heat Exchangers

- 2.1.1.

Fixed-Tube-Sheet Heat Exchanger (BEM)

-

- 2.1.2. U � Tube Heat Exchanger (CFU)

-

- 2.1.3. Packed-Lantern-Ring Heat Exchanger (AJW)

-

- 2.1.4. Outside Packed Floating Head Exchanger (AEP)

-

- 2.1.5. Internal Floating Head Exchanger (AES)

-

- 2.1.6. Kettle type - Pull-Through Floating Head

Exchanger (Reboiler / AKT)

- 2.2. Construction

- 2.2.1. Exploded

views of Fixed-Tube-Sheet Heat Exchanger

- 2.2.2. Exploded

views of U � Tube Heat

Exchanger

- 2.2.3. Exploded

views of

Packed-Lantern-Ring Heat

Exchanger

- 2.2.4. Exploded

views of Outside Packed

Floating Head Exchanger

- 2.2.5. Exploded

views of Internal

Floating Head Exchanger

- 2.2.6. Exploded

views of Pull-Through

Floating Head Exchanger

- 2.3. Hydraulic Pressure Testing and

related Maintenance details

- 2.3.1.

Fixed-Tube-Sheet Heat Exchanger

- 2.3.2. U � Tube Heat

Exchanger

- 2.3.3.

Packed-Lantern-Ring Heat

Exchanger

- 2.3.4. Outside

Packed Floating Head

Exchanger

- 2.3.5. Internal

Floating Head Exchanger

- 2.3.6. Pull-Through

Floating Head

- 2.4. Tube-Side construction

- 2.4.1. Tube-Side

Header

- 2.4.2. Bonnet

- 2.4.3. Channel

- 2.4.4. High Pressure

Closures

- 2.4.5. Tube-Side

Passes

- 2.4.6. Integrally

Finned Tubes

- 2.4.7. Tube Layout

- 2.4.8. Tube Sheet

- 2.4.9. Rolled Tube

Joints

- 2.4.10. Welded Tube

Joints

- 2.4.11. Tubes and

Tolerances

- 2.5. Shell-Side Construction

- 2.5.1. Shell Sizes

- 2.5.2. Shell Side

Arrangements

- 2.6. Baffles and Tube Bundles

- 2.6.1. Segmental

Baffles

- 2.6.2. Tie Rods and

Spacers

- 2.6.3. Impingement

Baffles

- 2.6.4. Vapor

Distribution

- 2.6.5. Tube-Bundle

Bypassing

- 2.6.6. Longitudinal

Baffles

- 3. Air Cooled Exchangers

- 3.1.Operation � Flow Path across the exchanger

- 3.2.Exploded views

- 3.3.Maintenance details

- 4. Plate and Frame Exchangers

- 4.1.Operation � Flow Path across the exchanger

- 4.2.Exploded views

- 5. Understanding TEMA

-

- 5.1. Selection and Game on TEMA

types

-

- 5.1.1. Front End

Stationary Head Type

-

5.1.1.1. Channel and

Removable Cover

-

- 5.1.1.2. Bonnet (Integral Cover)

-

- 5.1.1.3. Channel integral with

Tube-Sheet and Removable Cover

-

- 5.1.1.4. Channel integral with Shell

and Removable Cover

-

- 5.1.1.5. Special High Pressure

Closure

- 5.1.2. Shell Types

-

5.1.2.1. One Pass Shell

-

5.1.2.2.

Two Pass

Shell

with

Longitudinal

Baffle

-

5.1.2.3.

Split

Flow

-

5.1.2.4.

Double

Split

Flow

-

5.1.2.5.

Divided

Flow

-

5.1.2.6.

Kettle

type

Re-boiler

-

5.1.2.7.

Cross

Flow

- 5.1.3. Rear End Head

Type

-

5.1.3.1. Fixed Tube type

� �A� Stationary Head

-

5.1.3.2.

Fixed

Tube

type �

�B�

Stationary

Head

-

5.1.3.3.

Fixed

Tube

type �

�N�

Stationary

Head

-

5.1.3.4.

Guided

Packed

Floating

Head

-

5.1.3.5.

Out side

Packed

Floating

Head

-

5.1.3.6.

Floating

Head

with

Backing

Device

-

5.1.3.7.

Pull-Through

Floating

Head

-

5.1.3.8.

U � Tube

Bundle

-

5.1.3.9.

Externally

Sealed

Floating

Head

- 5.2. Skills Test

- 6. Glossary of Technical Terms

- 7. Conventional and Interactive Skill Tests with

evaluation

|

Email confirming

CD order sent immediately after purchase. After CD and Hardware Lock ships, an email will

be sent to confirm shipment.

|

|

|

|

|

|

|

Automated download

system is powered by our preferred method of payment, secure Pay Pal.

(After purchase, you receive a confirmation email.)

If you prefer us to manually process your order or would like to mail

or fax order in, please click CD

and Book Order Form on our secure servers at BIN95.

|

This guide, with skills tests, makes a great animated study

guide for related career skill assessment.

Heat Exchangers

CBT

The above picture is just a screen shot,

click for animated demo.

Heat Exchangers CBT Demo - Content

|

Heat Exchangers CBT Software |

| ESBN: II1-6798-6040-KM70 |

| Description:

This computer based training on Heat Exchangers

covers a large range of exchanger types like Shell &

Tube Exchangers (includes TEMA type

classification), Air-Cooled Exchanger, Plate &

Frame (Plate Exchanger), Spiral Exchanger, etc. Detailed

coverage provided on Heat Exchanger Operation &

Maintenance of popular TEMA - AES, BEM, AEP, CFU, AKT &

AJW types.

The focus on Heat Exchanger graphics/animation in the CBT helps

in very clearly understanding Heat Exchanger operating/working

principle & Heat Exchanger maintenance procedures like testing

and Heat Exchanger repair. The Heat Exchanger

training program provides detailed explanations of Heat

Exchanger assembly and dismantling. Animated

scenes give a deep insight into how Heat Exchangers work.

- Large range of Heat Exchangers covered

- Popular Exchangers like "Shell and Tube" covered in great

detail

- Extensive 2D / 3D graphics, models and animations

- Games on TEMA selection - over 250 exchangers can be

assembled!

- Glossary, Skills Tests and Certificate Printouts

Special Bonus:

Upon

request, we will embed your company logo (replacing the BIN95

logo) in the compressor training software, both to give you a

customized feel as well as for added protection of your new

company software. (Please note URL of

company logo in comment are when ordering or email your logo to

us, if you would like to take advantage of this new feature.)

Who

Can Benefit

Students as well as maintenance and engineering

personnel who have not had formal training, will

find this heat exchanger CBT increases both their knowledge and confidence

when working with most compressors and compressor control

systems. Those with previous air

compressor training may find this tutorial a good refresher and

may learn some important information not covered in their original

air compressor training.

The "Add

to Cart" Button below is for the Single User Version ONLY!

Hardware

Lock

The Heat

Exchangers CBT is different than our other training software

in the respect that it utilizes a "Hardware Lock"

licensing method. Many users have requested that they be able to

use the CD on multiple computers, like when working on the office computer and on their home

computer. This Hardware Lock method allows users to install the software on as many computers as they like.

They need only plug the key in which ever computer they are

currently wanting to use the software on. This copyright method

also works great for the class room environment.

Please click for multiple Workstations

and Network

Editions and special school pricing.

|

|

Email confirming

CD order sent immediately after purchase. After CD and Hardware Lock ships, an email will

be sent to confirm shipment.

|

|

|

|

|

|

|

Automated download

system is powered by our preferred method of payment, secure Pay Pal.

(After purchase, you receive a confirmation

email.) If you prefer us to manually process your order

or would like to mail or fax order in, please click CD

and Book Order Form on our secure servers at BIN95.

Course

Table

of Contents

- 1. Different Types of Heat Exchangers

- 1.1. Introduction

- 1.2. Shell and Tube Heat Exchanger

- 1.3. Air Cooled Heat Exchanger

- 1.4. Spiral Plate Heat Exchanger

- 1.5. Plate and Frame Heat Exchanger

- 1.6. Plate and Fin Heat Exchanger

- 1.7. Evaporative Cooled Heat Exchanger

- 1.8. Spiral Tube Heat Exchanger

- 1.9. Double Pipe Heat Exchanger

- 1.10. Bayonet Heat Exchanger

- 1.11. Patterned Plate Heat Exchanger

- 1.12. Mechanically aided (Scraped Surface Exchanger

& Thin Film Exchanger)

- 1.13. Jacketed Vessels

- 1.14. Fired Heaters

- 1.15. Regenerative Heat Exchanger

- 2. Detailed Description of Popular Shell and Tube

Exchangers

-

- 2.1. Principle of operation of Shell

and Tube Heat Exchangers

- 2.1.1.

Fixed-Tube-Sheet Heat Exchanger (BEM)

-

- 2.1.2. U � Tube Heat Exchanger (CFU)

-

- 2.1.3. Packed-Lantern-Ring Heat Exchanger (AJW)

-

- 2.1.4. Outside Packed Floating Head Exchanger (AEP)

-

- 2.1.5. Internal Floating Head Exchanger (AES)

-

- 2.1.6. Kettle type - Pull-Through Floating Head

Exchanger (Reboiler / AKT)

- 2.2. Construction

- 2.2.1. Exploded

views of Fixed-Tube-Sheet Heat Exchanger

- 2.2.2. Exploded

views of U � Tube Heat

Exchanger

- 2.2.3. Exploded

views of

Packed-Lantern-Ring Heat

Exchanger

- 2.2.4. Exploded

views of Outside Packed

Floating Head Exchanger

- 2.2.5. Exploded

views of Internal

Floating Head Exchanger

- 2.2.6. Exploded

views of Pull-Through

Floating Head Exchanger

- 2.3. Hydraulic Pressure Testing and

related Maintenance details

- 2.3.1.

Fixed-Tube-Sheet Heat Exchanger

- 2.3.2. U � Tube Heat

Exchanger

- 2.3.3.

Packed-Lantern-Ring Heat

Exchanger

- 2.3.4. Outside

Packed Floating Head

Exchanger

- 2.3.5. Internal

Floating Head Exchanger

- 2.3.6. Pull-Through

Floating Head

- 2.4. Tube-Side construction

- 2.4.1. Tube-Side

Header

- 2.4.2. Bonnet

- 2.4.3. Channel

- 2.4.4. High Pressure

Closures

- 2.4.5. Tube-Side

Passes

- 2.4.6. Integrally

Finned Tubes

- 2.4.7. Tube Layout

- 2.4.8. Tube Sheet

- 2.4.9. Rolled Tube

Joints

- 2.4.10. Welded Tube

Joints

- 2.4.11. Tubes and

Tolerances

- 2.5. Shell-Side Construction

- 2.5.1. Shell Sizes

- 2.5.2. Shell Side

Arrangements

- 2.6. Baffles and Tube Bundles

- 2.6.1. Segmental

Baffles

- 2.6.2. Tie Rods and

Spacers

- 2.6.3. Impingement

Baffles

- 2.6.4. Vapor

Distribution

- 2.6.5. Tube-Bundle

Bypassing

- 2.6.6. Longitudinal

Baffles

- 3. Air Cooled Exchangers

- 3.1.Operation � Flow Path across the exchanger

- 3.2.Exploded views

- 3.3.Maintenance details

- 4. Plate and Frame Exchangers

- 4.1.Operation � Flow Path across the exchanger

- 4.2.Exploded views

- 5. Understanding TEMA

-

- 5.1. Selection and Game on TEMA

types

-

- 5.1.1. Front End

Stationary Head Type

-

5.1.1.1. Channel and

Removable Cover

-

- 5.1.1.2. Bonnet (Integral Cover)

-

- 5.1.1.3. Channel integral with

Tube-Sheet and Removable Cover

-

- 5.1.1.4. Channel integral with Shell

and Removable Cover

-

- 5.1.1.5. Special High Pressure

Closure

- 5.1.2. Shell Types

-

5.1.2.1. One Pass Shell

-

5.1.2.2.

Two Pass

Shell

with

Longitudinal

Baffle

-

5.1.2.3.

Split

Flow

-

5.1.2.4.

Double

Split

Flow

-

5.1.2.5.

Divided

Flow

-

5.1.2.6.

Kettle

type

Re-boiler

-

5.1.2.7.

Cross

Flow

- 5.1.3. Rear End Head

Type

-

5.1.3.1. Fixed Tube type

� �A� Stationary Head

-

5.1.3.2.

Fixed

Tube

type �

�B�

Stationary

Head

-

5.1.3.3.

Fixed

Tube

type �

�N�

Stationary

Head

-

5.1.3.4.

Guided

Packed

Floating

Head

-

5.1.3.5.

Out side

Packed

Floating

Head

-

5.1.3.6.

Floating

Head

with

Backing

Device

-

5.1.3.7.

Pull-Through

Floating

Head

-

5.1.3.8.

U � Tube

Bundle

-

5.1.3.9.

Externally

Sealed

Floating

Head

- 5.2. Skills Test

- 6. Glossary of Technical Terms

- 7. Conventional and Interactive Skill Tests with

evaluation

|

Email confirming

CD order sent immediately after purchase. After CD and Hardware Lock ships, an email will

be sent to confirm shipment.

|

|

|

|

|

|

|

Automated download

system is powered by our preferred method of payment, secure Pay Pal.

(After purchase, you receive a confirmation email.)

If you prefer us to manually process your order or would like to mail

or fax order in, please click CD

and Book Order Form on our secure servers at BIN95.

|

|

|

|