Distillation CBT

|

|

| This guide, with skills tests, makes a great animated study guide for related career skill assessment.Distillation Process and Equipment Training

The above picture is just a screen shot, click for animated demo. Distillation CBT Demo - Content | Distillation Process and Equipment Training | | ESBN: YY1-6798-6040-OQ70 | | Description: The distillation process training program covers the various distillation practices including fractional distillation in explicit detail. The distillation process training program intricately covers vapor liquid equilibrium and covers topics like pressure temperature, phase diagram, constant pressure equilibrium, relative volatility, constant temperature equilibrium, Raoult�s Law, Mccabe-thiele method, etc. towards providing an in-depth understanding on the Distillation Process. The primary focus on graphic/animation in the software helps in very clearly understanding the distillation process, distillation operating/working principle and the construction and operation of distillation columns. - Vapor-liquid equilibrium and related principles covered in detail

- Various distillation practices described

- Detailed coverage on fractionation equipment & operation

- In-depth understanding achieved by 2D / 3D Graphics, Models & Animations

- Skill tests, Certificate printouts

Special Bonus: Upon request, we will embed your company logo (replacing the BIN95 logo) in the compressor training software, both to give you a customized feel as well as for added protection of your new company software. (Please note URL of company logo in comment are when ordering or email your logo to us, if you would like to take advantage of this new feature.) Who Can Benefit Students as well as maintenance and engineering personnel who have not had formal training, will find this computer based training on the distillation process and equipment increases both their knowledge and confidence when working. Those with previous training may find this tutorial a good refresher and may learn some important information not covered in their original training. Hardware Lock The CBT software on distillation utilizes a "Hardware Lock" licensing method. Many users have requested that they be able to use the CD on multiple computers, like when working on the office computer and on their home computer. This Hardware Lock method allows users to install the software on as many computers as they like. They need only plug the key in which ever computer they are currently wanting to use the software on. This copyright method also works great for the class room environment. Please click for multiple Workstations and Network Editions and special school pricing. | Email confirming CD order sent immediately after purchase. After CD and Hardware Lock ships, an email will be sent to confirm shipment. | | | |

Automated download system is powered by our preferred method of payment, secure Pay Pal. (After purchase, you receive a confirmation email.) If you prefer us to manually process your order or would like to mail or fax order in, please click CD and Book Order Form on our secure servers at BIN95.

Course Table of Contents- 1. Introduction

- 2. Vapor-liquid Equilibria and Distillation Process

- 2.1. Pressure � Temperature - Concentration Phase Diagram

- 2.2. Constant - Pressure Equilibria

- 2.3. Constant - Temperature Equilibria

- 2.4. Relative Volatility

- 2.5. Raoult's Law

- 2.6. Positive deviations from ideality � Min. Boiling Mixtures � Azeotropes

- 2.7. Negative deviations from ideality � Max. Boiling Mixtures � Azeotropes

- 2.8. Homogenous Azeotropes

- 2.9. Positive deviations from ideality - Heterogenous Azeotropes

- 2.10. Positive deviations from ideality - Insoluble Liquids

- 2.11. Multicomponent Systems

- 3. Distillation Process practices

- 3.1. Flash Distillation

- 3.2. Simple Distillation / Differential Distillation

- 3.3. Continuous Distillation with Rectification (Reflux Distillation)

- 3.4. Continuous Distillation with Rectification and Stripping � Fractional Distillation

- 3.5. Analysis of Fractionating Column - McCabe-Thiele method

3.5.1. Rectification Section 3.5.2. Stripping Section - 3.5.3. Introduction of Feed

- 3.5.4. Construction of Operating Lines

- 3.5.5. Number of Stages and Trays

- 3.5.6. Total Reflux

- 3.5.7. Minimum Reflux Ratio

- 3.5.8. Optimum Reflux Ratio

- 3.5.9. Multiple feeds

- 3.6. Fractionation - Packed Towers

- 3.7. Fractionation � Multicomponent systems

- 3.8. Petroleum Refining

- 3.9. Vacuum distillation

- 3.10. Steam distillation

- 3.11. Destructive distillation

- 3.12. Azeotropic distillation

- 3.13. Extractive distillation

4. Fractionation equipment and operation - 4.1. Shell

4.2. Distillation Column Internals (Distillation Tower Internals) 4.2.1. Distillation Tray Towers - 4.2.1.1. Weir and Liquid depth

- 4.2.1.2. Flow arrangements

- 4.2.1.3. Tray Types

- 4.2.1.3.1. Bubble Cap Trays

- 4.2.1.3.2. Sieve Trays

- 4.2.1.3.3. Valve Trays

- 4.2.2. Distillation Packed Towers

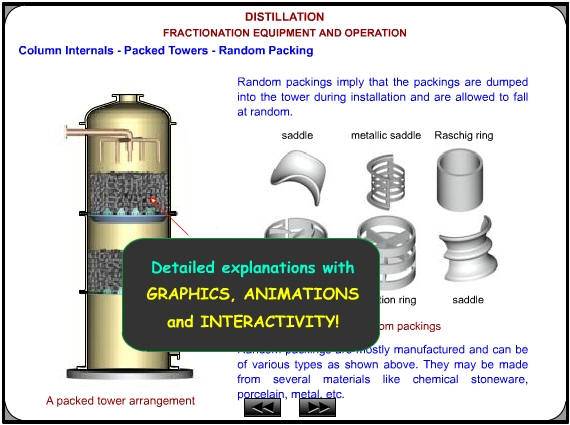

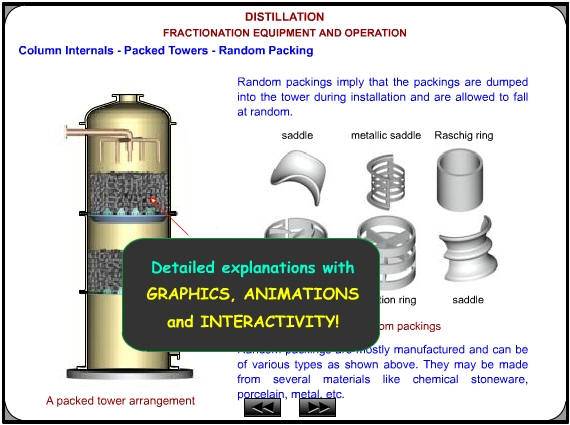

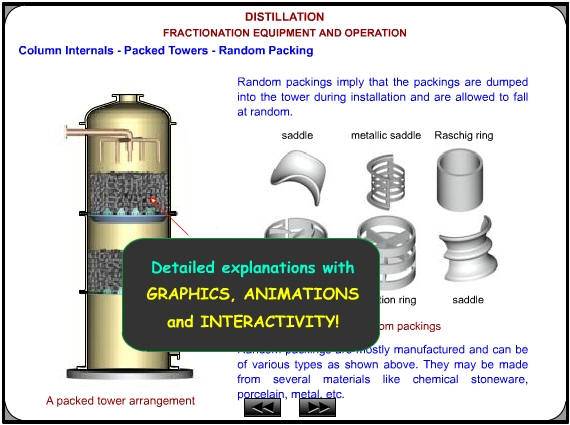

- 4.2.2.1. Random Packing

- 4.2.2.2. Regular Packing

- 4.2.2.3. Packing supports

- 4.2.2.4. Liquid Distributors

- 4.2.2.5. Other Components

- 4.3. Reboiler

- 4.3.1. Jacketed vessel Reboiler

- 4.3.2. Built-in Reboiler

- 4.3.3. Kettle-type Reboiler

- 4.3.4. Thermosiphon Reboilers

4.4. Condenser / Reflux Drum - 4.4.1. Total Condenser

- 4.4.2. Partial Condenser

4.5. Operation of Tray and Packed Towers

5. Conventional and Interactive Skill Tests with Evaluation

Email confirming CD order sent immediately after purchase. After CD and Hardware Lock ships, an email will be sent to confirm shipment. | | | |

Automated download system is powered by our preferred method of payment, secure Pay Pal. (After purchase, you receive a confirmation email.) If you prefer us to manually process your order or would like to mail or fax order in, please click CD and Book Order Form on our secure servers at BIN95. |

This guide, with skills tests, makes a great animated study guide for related career skill assessment.Distillation Process and Equipment Training

The above picture is just a screen shot, click for animated demo. Distillation CBT Demo - Content | Distillation Process and Equipment Training | | ESBN: YY1-6798-6040-OQ70 | | Description: The distillation process training program covers the various distillation practices including fractional distillation in explicit detail. The distillation process training program intricately covers vapor liquid equilibrium and covers topics like pressure temperature, phase diagram, constant pressure equilibrium, relative volatility, constant temperature equilibrium, Raoult�s Law, Mccabe-thiele method, etc. towards providing an in-depth understanding on the Distillation Process. The primary focus on graphic/animation in the software helps in very clearly understanding the distillation process, distillation operating/working principle and the construction and operation of distillation columns. - Vapor-liquid equilibrium and related principles covered in detail

- Various distillation practices described

- Detailed coverage on fractionation equipment & operation

- In-depth understanding achieved by 2D / 3D Graphics, Models & Animations

- Skill tests, Certificate printouts

Special Bonus: Upon request, we will embed your company logo (replacing the BIN95 logo) in the compressor training software, both to give you a customized feel as well as for added protection of your new company software. (Please note URL of company logo in comment are when ordering or email your logo to us, if you would like to take advantage of this new feature.) Who Can Benefit Students as well as maintenance and engineering personnel who have not had formal training, will find this computer based training on the distillation process and equipment increases both their knowledge and confidence when working. Those with previous training may find this tutorial a good refresher and may learn some important information not covered in their original training. Hardware Lock The CBT software on distillation utilizes a "Hardware Lock" licensing method. Many users have requested that they be able to use the CD on multiple computers, like when working on the office computer and on their home computer. This Hardware Lock method allows users to install the software on as many computers as they like. They need only plug the key in which ever computer they are currently wanting to use the software on. This copyright method also works great for the class room environment. Please click for multiple Workstations and Network Editions and special school pricing. | Email confirming CD order sent immediately after purchase. After CD and Hardware Lock ships, an email will be sent to confirm shipment. | | | |

Automated download system is powered by our preferred method of payment, secure Pay Pal. (After purchase, you receive a confirmation email.) If you prefer us to manually process your order or would like to mail or fax order in, please click CD and Book Order Form on our secure servers at BIN95.

Course Table of Contents- 1. Introduction

- 2. Vapor-liquid Equilibria and Distillation Process

2.1. Pressure � Temperature - Concentration Phase Diagram 2.2. Constant - Pressure Equilibria 2.3. Constant -Temperature Equilibria 2.4. Relative Volatility 2.5. Raoult's Law 2.6. Positive deviations from ideality � Min. Boiling Mixtures � Azeotropes 2.7. Negative deviations from ideality � Max. Boiling Mixtures � Azeotropes 2.8. Homogenous Azeotropes 2.9. Positive deviations from ideality - Heterogenous Azeotropes 2.10. Positive deviations from ideality - Insoluble Liquids 2.11. Multicomponent Systems

3. Distillation Process practices - 3.1. Flash Distillation

- 3.2. Simple Distillation / Differential Distillation

- 3.3. Continuous Distillation with Rectification (Reflux Distillation)

- 3.4. Continuous Distillation with Rectification and Stripping � Fractional Distillation

- 3.5. Analysis of Fractionating Column - McCabe-Thiele method

3.5.1. Rectification Section 3.5.2. Stripping Section

- 3.5.3. Introduction of Feed

- 3.5.4. Construction of Operating Lines

- 3.5.5. Number of Stages and Trays

- 3.5.6. Total Reflux

- 3.5.7. Minimum Reflux Ratio

- 3.5.8. Optimum Reflux Ratio

- 3.5.9. Multiple feeds

- 3.6. Fractionation - Packed Towers

- 3.7. Fractionation � Multicomponent systems

- 3.8. Petroleum Refining

- 3.9. Vacuum distillation

- 3.10. Steam distillation

- 3.11. Destructive distillation

- 3.12. Azeotropic distillation

- 3.13. Extractive distillation

4. Fractionation equipment and operation - 4.1. Shell

4.2. Distillation Column Internals (Distillation Tower Internals) 4.2.1. Distillation Tray Towers - 4.2.1.1. Weir and Liquid depth

- 4.2.1.2. Flow arrangements

- 4.2.1.3. Tray Types

- 4.2.1.3.1. Bubble Cap Trays

- 4.2.1.3.2. Sieve Trays

- 4.2.1.3.3. Valve Trays

- 4.2.2. Distillation Packed Towers

- 4.2.2.1. Random Packing

- 4.2.2.2. Regular Packing

- 4.2.2.3. Packing supports

- 4.2.2.4. Liquid Distributors

- 4.2.2.5. Other Components

- 4.3. Reboiler

- 4.3.1. Jacketed vessel Reboiler

- 4.3.2. Built-in Reboiler

- 4.3.3. Kettle-type Reboiler

- 4.3.4. Thermosiphon Reboilers

4.4. Condenser / Reflux Drum - 4.4.1. Total Condenser

- 4.4.2. Partial Condenser

4.5. Operation of Tray and Packed Towers

5. Conventional and Interactive Skill Tests with Evaluation

Email confirming CD order sent immediately after purchase. After CD and Hardware Lock ships, an email will be sent to confirm shipment. | | | |

Automated download system is powered by our preferred method of payment, secure Pay Pal. (After purchase, you receive a confirmation email.) If you prefer us to manually process your order or would like to mail or fax order in, please click CD and Book Order Form on our secure servers at BIN95. |

|

|