|

| This guide, with skills tests, makes a great animated study guide for related career skill assessment.Centrifugal Pump & Troubleshooting Guide

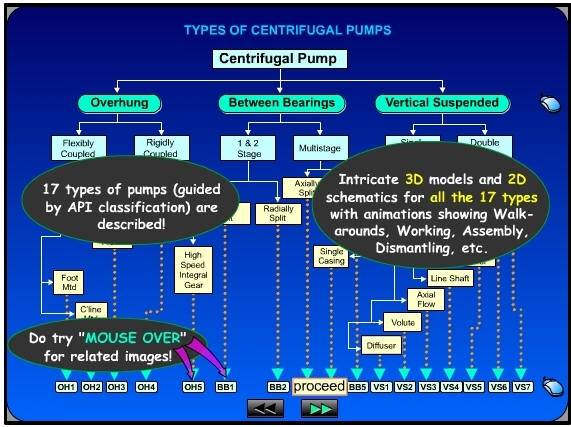

The above picture is just a screen shot, click for animated demo. Centrifugal Pump Demo - Content

Automated download system is powered by our preferred method of payment, secure Pay Pal. (After purchase, you receive a confirmation email.) If you prefer us to manually process your order or would like to mail or fax order in, please click CD and Book Order Form on our secure servers at BIN95.

Course Table of Contents1. Introduction 2.1. Centrifugal Pumps 2.4.1. Suction Design 2.4.1.1. Single 2.4.1.2. Double 2.4.2. Number of Stages 2.4.2.1. Single 2.4.3. Guide Vanes 2.4.3.1. Volute 2.4.4. Casing Construction 2.4.4.1. Radially Split 2.4.5. Impeller Shrouds 2.4.5.1. Open 2.4.6. Shaft Position 2.4.6.1. Horizontal 3. Centrifugal Pump Basics 3.1. Principle of Operation 4. API � 610 Types and features 4.1. Overhung 4.1.1. Flexibly Coupled 4.1.1.1. Horizontal 4.1.1.1.1. Foot Mounted : OH1 4.1.1.2. Vertical 4.1.1.2.1. In-line Bearing Frame : OH3 4.1.2. Rigidly Coupled 4.1.2.1. Vertical 4.1.2.1.1. In-line : OH4 4.1.2.2. High Speed Integral Gear : OH5 4.2. Between Bearing 4.2.1. 1st and 2nd Stage 4.2.1.1. Axially Split : BB1 4.2.2. Multistage 4.2.2.1. Axially Split : BB3 4.2.2.2.1. Single Casing : BB4 4.3. Vertical Suspended 4.3.1. Single Casing 4.3.1.1. Discharge Through Column 4.3.1.1.1. Diffuser : VS1 4.3.1.2. Separate Discharge (Sump) 4.3.1.2.1. Line Shaft : VS4 4.3.2. Double Casing 4.3.2.1. Diffuser : VS6 4.4. Wear Ring Running Clearances 5. Conventional and Interactive Skill Tests with evaluation 6.1. Overhung Pump � OH 7. Technical Glossary � Failure or deviation symptoms o Pump does not deliver � Around 45 specific root-causes have been identified similar to the few listed below: o Pump not primed

Automated download system is powered by our preferred method of payment, secure Pay Pal. (After purchase, you receive a confirmation email.) If you prefer us to manually process your order or would like to mail or fax order in, please click CD and Book Order Form on our secure servers at BIN95. |

This guide, with skills tests, makes a great animated study guide for related career skill assessment.Centrifugal Pump & Troubleshooting Guide

The above picture is just a screen shot, click for animated demo. Centrifugal Pump Demo - Content

Automated download system is powered by our preferred method of payment, secure Pay Pal. (After purchase, you receive a confirmation email.) If you prefer us to manually process your order or would like to mail or fax order in, please click CD and Book Order Form on our secure servers at BIN95.

Course Table of Contents1. Introduction 2.1. Centrifugal Pumps 2.4.1. Suction Design 2.4.1.1. Single 2.4.1.2. Double 2.4.2. Number of Stages 2.4.2.1. Single 2.4.3. Guide Vanes 2.4.3.1. Volute 2.4.4. Casing Construction 2.4.4.1. Radially Split 2.4.5. Impeller Shrouds 2.4.5.1. Open 2.4.6. Shaft Position 2.4.6.1. Horizontal 3. Centrifugal Pump Basics 3.1. Principle of Operation 4. API � 610 Types and features 4.1. Overhung 4.1.1. Flexibly Coupled 4.1.1.1. Horizontal 4.1.1.1.1. Foot Mounted : OH1 4.1.1.2. Vertical 4.1.1.2.1. In-line Bearing Frame : OH3 4.1.2. Rigidly Coupled 4.1.2.1. Vertical 4.1.2.1.1. In-line : OH4 4.1.2.2. High Speed Integral Gear : OH5 4.2. Between Bearing 4.2.1. 1st and 2nd Stage 4.2.1.1. Axially Split : BB1 4.2.2. Multistage 4.2.2.1. Axially Split : BB3 4.2.2.2.1. Single Casing : BB4 4.3. Vertical Suspended 4.3.1. Single Casing 4.3.1.1. Discharge Through Column 4.3.1.1.1. Diffuser : VS1 4.3.1.2. Separate Discharge (Sump) 4.3.1.2.1. Line Shaft : VS4 4.3.2. Double Casing 4.3.2.1. Diffuser : VS6 4.4. Wear Ring Running Clearances 5. Conventional and Interactive Skill Tests with evaluation 6.1. Overhung Pump � OH 7. Technical Glossary � Failure or deviation symptoms o Pump does not deliver � Around 45 specific root-causes have been identified similar to the few listed below: o Pump not primed

Automated download system is powered by our preferred method of payment, secure Pay Pal. (After purchase, you receive a confirmation email.) If you prefer us to manually process your order or would like to mail or fax order in, please click CD and Book Order Form on our secure servers at BIN95. | |||||||||||

|