Product description:

This Basic Hydraulics Training Course (The Fluid Power Trainer) uses pneumatic and industrial hydraulic training simulations to instruct the learner in the fluid power principles and ISO CETOP hydraulics schematics symbols. Learn how to read schematics, and understand how pneumatic and hydraulic systems operate in order to troubleshoot hydraulics and pneumatics systems effectively. Learn much more than just how hydraulics works, the course even touches on vacuum systems.

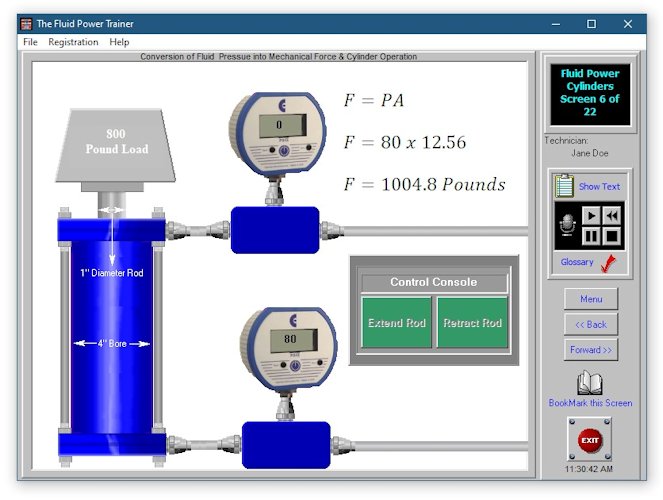

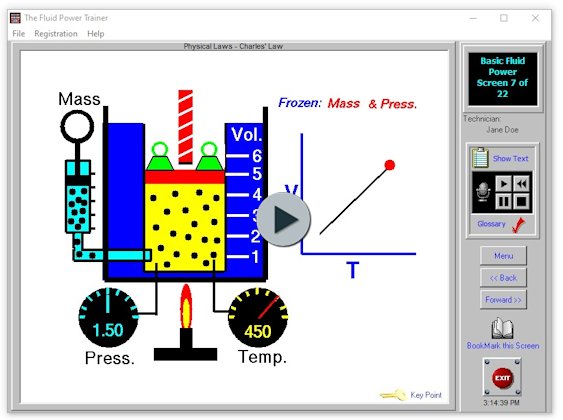

Basic fluid power formulas are explained and demonstrated with the hydraulic and pneumatic simulator in an interactive way so student can experience all vantage points and values. A task that would otherwise be difficult to visualize just by listening to a lecture or reading a book. As a plant compressed air system is a type of fluid power control, this course helps maintenance keep their compressed pneumatics online. The course wraps up with a troubleshooting section.

This basic industrial hydraulics training course (the Fluid Power Trainer), typically takes about 25 hours to earn a certificate. If an instructor goes through the Lab manual exercises with a class, it could extend class hours. It is a software course to be installed on a Windows computer, so it never expires, learners can use it on their own schedule and use it as a refresher. Available as a single Student learner license, unlimited-user Site License, and unlimited-sites Enterprise License for schools and companies. Most online and software courses' amount of interactivity is no more than flipping to the next screen and answering some written questions, our courses are the exception. This course on industrial control includes videos, animations, and even simulations! So the learner understands better and retains knowledge longer.

Also, the included 62-page PDF Laboratory Manual is full of proven practical exercises, assignment sheets, and quizzes that allow the learner to gain a better understanding of the fluid power course. Also included with the course is a PDF industrial hydraulics glossary. The lab manual is written for the instructor to use with their students when a school is purchasing a site and enterprise licenses. A single Student learner license holder (individuals), also has access to the lab manual, as extra learning material, not required for the certificate completion.

[The video below shows Fluid Power Training software in use and lets you hear audio narration sample. (Koldwater is a subsidiary of BIN95)]

Hydraulics Training Course Sections:

- ✔Basic Industrial Hydraulics & Pneumatics Principles

- ✔Pneumatic and Hydraulic Schematics Symbols

- ✔How Hydraulic and Pneumatic Cylinders Work

- ✔How Hydraulic and Pneumatic Control Valves Work

- ✔Fluid Power 3-Way & 4-Way Valves

- ✔Fluid Power 4-Way & 5-Way Valves

- ✔Understanding Pneumatic Hydraulic Pump Workings

- ✔Pneumatic & Hydraulic Components

- ✔Pneumatic & Hydraulic Troubleshooting

Also included: * Final Exam * Laboratory Manual * Password protected MS Access Student Log File (Site & Enterprise License only) * Ability to print Certificate of Completion * Ability to print test responses (Site & Enterprise License only) * Ability to bookmark * Mini LMS (Site & Enterprise License only)

License Types:

Student License - 1 student/learner may take the courses.

Site License - Unlimited students/installs at a single site [physical location].

Enterprise License - Unlimited Site Licenses/locations for school or company. (Request Quote at BIN95)

Please contact our mother company (BIN95) if your school or company wants to purchase unlimited-user site or enterprise license via purchase order.